Johnson Wedge Wire Screen Filter Element

A quick intro johnson wedge wire display design company suppliers makers ◊ The business with the largest export quantity of wedge cable screen filter items in North China( 3 consecutive years ). ◊ Three technological patents( processing modern technology and also

cleansing technology). ◊ Five wedge wire screen filter production lines, two filter aspect components assembly line, the introduction of intelligent manufacturing tools, rigorous control of product quality. ◊ The professional technological team can give wedge wire screen style services, CAD and also 3D illustrations for customers. ◊ Independent quality inspection division, from the purchase of raw products to the shipment assessment, each web link has an unique top quality inspection personnel, offering product examination certificate. ◊ Accumulated greater than 20 years of manufacturing experience, aware of making use of products in

numerous industries, can provide professional advice to consumers. Our tools Wedge cable screen welding equipment V cord attracting tools & Corrective equipment Argon arc welding, plasma welding, laser

welding, resistance welding, as well as intelligent arm welding devices Laser cutting as well as molybdenum wire reducing tools Milling device and also CNC device Marking equipment as well as rolling equipment Cleansing tools

Development and also field of expertise are our company culture. We only focus on the R & D as well as manufacturing of wedge internet item collection.

The invention of products is our objective. We are devoted to becoming the initial brand of steel filter components in China. ♠ Specifications of high precision all-welded wedge cord tube & pipeline wedge cord rotating display trommel screenIn order to solve the trouble of inadequate

roundness as well as irregular gap of wedge wire display tube, the bonded wedge cable display tube( wedge filter aspect) separately developed by BLUSLOT ™ FILTER has outstanding satiation and absolute gap. Product: stainless steel ss304, ss316, ss316l, paired 2205 and many other special alloy materials. Specs: 25, mm, 30mm, 36mm, 42mm, 45mm, 50mm, 60m, 65mm, 70mm, 76mm, 80mm, 86mm, 89mm, 110mm, 137mm, 189mm, 268mm, 305 as well as many various other requirements. Minimum slot dimension: 15 microns Port size: >/= 10 microns. Resistance: 5 microns. The minimal size of the welded cable wrapped display pipeline: 25 mm. Optimum size: 1800mm. Length: 2300mm.

The raw products are linked right into

high-quality cable products.

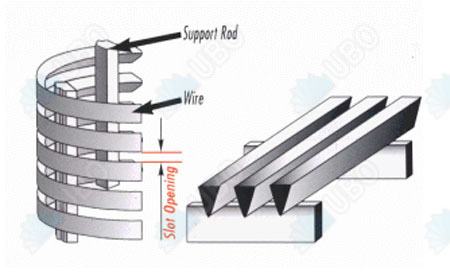

The raw materials, wire developing process as well as the top quality of items after welding of our items can satisfy global standards, as well as it can completely change the import, as well as the delivery time has a terrific benefit contrasted with foreign nations. The Vee cable filter component made by BLUSLOT FILTER is made up of V-shaped steel cable( profile cord) as well as assistance cord. The smooth surface area of the filter element is the filtering surface, which has a continual slotting framework as well as comes from the surface filtering system form. As the very best filter aspect of several kinds of automatic filters, it is commonly made use of in the deep filtering of the diatomite filter. Due to the special wedge cord structure, contrasted with sintered cord filter element as well as other filter aspects,

it has the advantages of hard to obstruct, easy to backwash as well as lengthy solution life, and also is the ideal replacement

for other filter elements. Wedge cable display applications( use) wedge cord screen basket companyA wedge wire screen is mostly made use of for commercial purification and separation. It can efficiently eliminate the solid fragments in the liquid, and likewise has strong chemical compatibility.

It can be utilized for the filtration of acid-base organic solvents. In enhancement, the utility model has the benefits of solid contaminant holding capability, longer solution life, as well as efficient sound reduction. Bluslot ™ developed a 10-micron port dimension products in 2015.

cleansing technology). ◊ Five wedge wire screen filter production lines, two filter aspect components assembly line, the introduction of intelligent manufacturing tools, rigorous control of product quality. ◊ The professional technological team can give wedge wire screen style services, CAD and also 3D illustrations for customers. ◊ Independent quality inspection division, from the purchase of raw products to the shipment assessment, each web link has an unique top quality inspection personnel, offering product examination certificate. ◊ Accumulated greater than 20 years of manufacturing experience, aware of making use of products in

numerous industries, can provide professional advice to consumers. Our tools Wedge cable screen welding equipment V cord attracting tools & Corrective equipment Argon arc welding, plasma welding, laser

welding, resistance welding, as well as intelligent arm welding devices Laser cutting as well as molybdenum wire reducing tools Milling device and also CNC device Marking equipment as well as rolling equipment Cleansing tools

Development and also field of expertise are our company culture. We only focus on the R & D as well as manufacturing of wedge internet item collection.

The invention of products is our objective. We are devoted to becoming the initial brand of steel filter components in China. ♠ Specifications of high precision all-welded wedge cord tube & pipeline wedge cord rotating display trommel screenIn order to solve the trouble of inadequate

roundness as well as irregular gap of wedge wire display tube, the bonded wedge cable display tube( wedge filter aspect) separately developed by BLUSLOT ™ FILTER has outstanding satiation and absolute gap. Product: stainless steel ss304, ss316, ss316l, paired 2205 and many other special alloy materials. Specs: 25, mm, 30mm, 36mm, 42mm, 45mm, 50mm, 60m, 65mm, 70mm, 76mm, 80mm, 86mm, 89mm, 110mm, 137mm, 189mm, 268mm, 305 as well as many various other requirements. Minimum slot dimension: 15 microns Port size: >/= 10 microns. Resistance: 5 microns. The minimal size of the welded cable wrapped display pipeline: 25 mm. Optimum size: 1800mm. Length: 2300mm.

The raw products are linked right into

high-quality cable products.

The raw materials, wire developing process as well as the top quality of items after welding of our items can satisfy global standards, as well as it can completely change the import, as well as the delivery time has a terrific benefit contrasted with foreign nations. The Vee cable filter component made by BLUSLOT FILTER is made up of V-shaped steel cable( profile cord) as well as assistance cord. The smooth surface area of the filter element is the filtering surface, which has a continual slotting framework as well as comes from the surface filtering system form. As the very best filter aspect of several kinds of automatic filters, it is commonly made use of in the deep filtering of the diatomite filter. Due to the special wedge cord structure, contrasted with sintered cord filter element as well as other filter aspects,

it has the advantages of hard to obstruct, easy to backwash as well as lengthy solution life, and also is the ideal replacement

for other filter elements. Wedge cable display applications( use) wedge cord screen basket companyA wedge wire screen is mostly made use of for commercial purification and separation. It can efficiently eliminate the solid fragments in the liquid, and likewise has strong chemical compatibility.

It can be utilized for the filtration of acid-base organic solvents. In enhancement, the utility model has the benefits of solid contaminant holding capability, longer solution life, as well as efficient sound reduction. Bluslot ™ developed a 10-micron port dimension products in 2015.

Our wedge cord screen filter items can be used to much more exact filter systems. The wedge cord screen has high pollutant holding capacity, high porosity, lengthy solution life, solid plasticity as well as mechanical

strength, exact filtering accuracy, and strong leaks in the structure. It is a suitable filter element with high accuracy and also heat.

It is very suitable for high-pressure backwash oil filters as well as dust elimination in a high-temperature setting. Wedge cable screens can be utilized as distributed cooling material in a high-temperature setting, in addition to pore plate product for gas distribution or fluidization bed. It can also be used for high-pressure backwash oil filter and also commonly utilized in aerospace, petrochemical, mechanical, chemical and also metallurgical industries. A wedge wire screen filter is an excellent filter aspect for purification, separation, as well as dewatering. It is extensively used in the pharmaceutical industry, petrochemical industry of high temperature level, destructive fluid filtering, mechanical sector of all type of hydraulic oil, lubricating oil filtration and also anti-riot device in the buzzer and so forth. Additionally, it is additionally made use of in polyester, food, beverage as well as oil, chemical fiber, water therapy, gas filtration, as well as various other industries. ATM MACHINE Advantages of Johnson wedge cord screen contrasted with woven cord mesh wedge wire screen cylinderJohnson display is a sieve plate constructed from stainless-steel wire by chilly rolling. Q235 edge constructed from the flat iron, used for filtering and also separation metal mesh framework. Main efficiency and also characteristics of

Johnson screen. It has great wear resistance and long service life.

Johnson display is various from a regular stainless steel cord woven mesh. Johnson level display is a kind of metal mesh used for display filtering. Material qualities, framework, product, screening machine criteria, evaluating ability, screening effectiveness as well as procedure thickness of the display plate.

When choosing the profile cable screen, we should acknowledge the factory of

the profile wire screen, display then and also quality of the goods. When the profile cable display is used to adjust the rotation direction of the electric motor, if the motor of the account wire screen rotates towards the inner

side wrongly, although the projection angle is also additionallyAhead the cuttings have the force pressure roll back, so the forward movement motion rate the cuttings will significantly substantially down. In order to lower the problem of screen altering as well as streamline the process of display altering as much as feasible, we upgraded the vibrating wedge cable display framework when developing the shaking screen.

Take out the turning display structure and location it on the display structure. Eliminate the embossing strip, get rid of the currently damaged screen, open the recently prepared new screen,

and then place it on the main screen primary display. In order to deal with the screen, the brand-new screen dimension is generally concerning 2cm larger than the needed size.

Use scissors to wedge in the cords. Cut off the remaining 2 cm screen along the edge of the screen

framework, as well as keep it at the side of the display. Put the sealant strip taken out of the screen bag back to the original direction of the screen, so as to reset the display as well as slowly eliminate the frame, put the diaphragm ring back on the screen, hit the area of the diaphragm ring equally with a soft hammer, and also tighten up the copper nut of the diaphragm ring. ATM MACHINE How to keep the oxide movie externally of the wedge cable display? After the oxidation movie externally of the wedge cord display is dealt with, the surface area is a layer of lusterless result. Although it appears to be gorgeous without

appeal, it is more functional. In the process of wedge wire screen filter processing, more protection ought to be supplied for edge rolling, welding, etc. There is a portable upkeep movie on the surface of the wedge cable screen, as well as the maintenance of the oxide film can enhance the efficient solution life of the wedge wire screen panels. There are 2 means to keep the curing membrane layer, one is the chemical technique and also the various other is a sandblasting approach. Next off, we will remain to present just how to preserve the oxide film.

Chemical approach: utilize a pickling passivation paste and also typical temperature cleaning remedy with inorganic ingredients for immersion.

In order to adapt to the setting, a protective film will certainly be covered on the surface of the wedge wire screen filter throughout the handling and also production, so as to protect against the rust of

the stainless steel product. ♠ Wire covered display laying. Prior to laying the wire covered display, we need to initially make the installment plan of the wedge wire mesh.

For the 2 ends of the bonded wire mesh that must be punctured right into the beam of light, when the longitudinal direction of the cord covered display is relatively slim, very first usage the flexing deformation function of the cable covered display to bend the center of the bonded wire mesh upward, so that the ends can be pierced right into the beam one by one. When one of the two-wire covered screen grids in the overlapping location has no transverse reinforcement, the smaller overlapping size of the ribbed cable covered screen grid shall be 1.3 times of the smaller sized anchorage

length La, and shall as well as will less than 300 mm. Wedge cable screens can be separated right into various shapes and kinds according to the diameter of the display surface area: rectangle-shaped and also round.

ATM MACHINE Comparison of the determined value of stress decline between the Johnson wedge cord display and woven cable mesh. In the oil and chemical sector and various other industries, the filter display is widely utilized in the procedure of liquid transport.

In current years, Johnson's wedge wire screen has actually replaced the standard woven mesh as well as orifice plate increasingly more, which is generally established by the special framework as well as lots of benefits of the wedge wire displays. In a particular series of pores, the fluid resistance drop of Johnson vee

wire screen is clearly smaller than that of the woven web and also pore plate structure. The calculation as well as contrast of resistance decrease in the style and also option of filter screen materials are of wonderful importance for the choice of filter display. Filter components of chemical pipe filters, grids of reactors, clothes dryers, and so on shall be evaluated. When the liquid passes

via the screen, there will certainly be a resistance decline. The resistance decrease is not only relevant to power consumption and also production price yet also straight affects the standing of the handling system, therefore impacting production performance and also item high quality. Therefore, without affecting the structure of the tools, lowering the resistance decrease of the filter screen can not just decrease energy consumption as well as manufacturing cost however also boost production effectiveness as well as item top quality. Characteristics of woven mesh. In China, the composite framework of the cable woven display as well as the porous plate is extensively made use of in the industry. As a result of the huge contact area between solid particles( driver, molecular sieve or numerous filter products) and also the screen, the fragments are simple to obstruct or get embeded the pores of the steel display or permeable plate, leading to raised pressure decline, costly media loss after bending

contortion, and also making the tool incapable to operate, Maintenance is additionally more tough. Characteristics of Johnson wedge wire display. Johnson screen utilizes a resistance welding approach to bond the metal cord with the form similar to V-shape on the assistance rod arranged up and down, developing a consistent as well as constant void, and also the filter just has two factors of call with the display surface. Because of the unique framework of the Johnson screen, it has many features that are not located in the woven mesh.

⇒ Each cross point of the cord and also the support pole is welded, with high accuracy and also exact space. ⇒ High toughness, large circulation price, high capacity, strong durability. ⇒ With the rise of opening range, opening up price as well as efficient flow location. ⇒ The space is continuous and also the mesh surface area is smooth, that makes the stimulant circulation smooth, wear less and also the bits are hard to be squashed. ⇒ Anti-blocking. ⇒ Wear resistance. Comparison in between Johnson display as well as woven web. There are apparent differences between both kinds of filter displays in their anti-blocking performance. As well as the stamina of the woven network is low, in the process of usage, it needs to be combined with the porous plate. The opening price of the composite structure is the item of the opening rate of the woven mesh and the porous plate, as well as the opening rate is considerably minimized. According to gb10612-89 and also GB/ t5330.1-2000, when the opening proportion of woven mesh and also the permeable plate

is 60 %and also 60% respectively, the item worth is just 36%. Due to the fact that of the different structures of the two sort of filter screens, also if the aspects such as obstructing are not thought about, the resistance decline of the liquid going through both type of filter screens is rather various in a particular variety of pores.

Wedge wire screen applications( usage) wedge wire display basket companyA wedge cable screen is mainly made use of for industrial filtration as well as separation. Product qualities, framework, material, evaluating equipment specifications, evaluating capacity, evaluating performance and procedure density of the display plate. In order to minimize the problem of screen altering and also simplify the process of screen changing as much as feasible, we upgraded the vibrating wedge cable display structure when developing the shaking screen. Cut off the continuing to be 2 centimeters screen along the edge of the screen

frame, structure keep it maintain the edge of the screen. Place the sealant strip taken out of the display bag back to the initial direction of the display, so as to reset the screen as well as gradually eliminate the structure, placed the diaphragm ring back on the display, struck the circumference of the diaphragm ring equally with a soft hammer, as well as tighten up the copper nut of the diaphragm ring.

If you want to learn more about Johnson Screen and Wedge Wire Screen, please visit: www.bluslot.com.

Johnson Wedge Wire Screen Filter Element

◊ Five wedge cable screen filter manufacturing lines, two filter element parts manufacturing lines, the introduction of intelligent production equipment, strict control of product high quality. ◊ The expert technical team can give wedge wire screen design services, CAD and also 3D illustrations for consumers. ◊ Accumulated even more than 20 years of production experience, acquainted with the use of products in

various industriesMarkets can give professional expert to customersClients

Advancement as well as field of expertise are our business culture. We just concentrate on the R & D and manufacturing of wedge web product collection.

We are dedicated to establishing into the first brand of metal filter elements in China. Product: stainless steel ss304, ss316, ss316l, duplex 2205 and lots of various other special alloy materials. The minimal size of the bonded cord wrapped screen pipe: 25 mm.

The raw products are merged into

high-quality cable materials.

The raw products, wire developing procedure and also the top quality of products after welding of our products can meet international criteria, and also it can completely change the import, and the shipment time has a fantastic advantage compared to foreign countries. The Vee cable filter component made by BLUSLOT FILTER is composed of V-shaped steel wire( account wire) and also assistance cable. The smooth surface of the filter component is the filtering surface area, which has a continual slotting structure as well as belongs to the surface filtering system kind. As the best filter element of lots of sort of automated filters, it is widely made use of in the deep purification of the diatomite filter. Because of the special wedge cable framework, compared to sintered cable filter component and also various other filter components,

it has the advantages of difficult to block, very easy to backwash as well as lengthy life span, and is the perfect substitute

for various other filter aspects. Wedge cable screen applications( use) wedge cord display basket companyA wedge wire screen is mainly utilized for commercial filtration as well as splitting up. It can effectively remove the strong bits in the liquid, as well as additionally has strong chemical compatibility.

It can be used for the filtering of acid-base natural solvents. In enhancement, the utility version has the benefits of strong toxin holding capability, longer life span, and also efficient noise reduction. Bluslot ™ created a 10-micron slot size items in 2015.

various industriesMarkets can give professional expert to customersClients

Advancement as well as field of expertise are our business culture. We just concentrate on the R & D and manufacturing of wedge web product collection.

We are dedicated to establishing into the first brand of metal filter elements in China. Product: stainless steel ss304, ss316, ss316l, duplex 2205 and lots of various other special alloy materials. The minimal size of the bonded cord wrapped screen pipe: 25 mm.

The raw products are merged into

high-quality cable materials.

The raw products, wire developing procedure and also the top quality of products after welding of our products can meet international criteria, and also it can completely change the import, and the shipment time has a fantastic advantage compared to foreign countries. The Vee cable filter component made by BLUSLOT FILTER is composed of V-shaped steel wire( account wire) and also assistance cable. The smooth surface of the filter component is the filtering surface area, which has a continual slotting structure as well as belongs to the surface filtering system kind. As the best filter element of lots of sort of automated filters, it is widely made use of in the deep purification of the diatomite filter. Because of the special wedge cable framework, compared to sintered cable filter component and also various other filter components,

it has the advantages of difficult to block, very easy to backwash as well as lengthy life span, and is the perfect substitute

for various other filter aspects. Wedge cable screen applications( use) wedge cord display basket companyA wedge wire screen is mainly utilized for commercial filtration as well as splitting up. It can effectively remove the strong bits in the liquid, as well as additionally has strong chemical compatibility.